Mitigate Supplier Risk

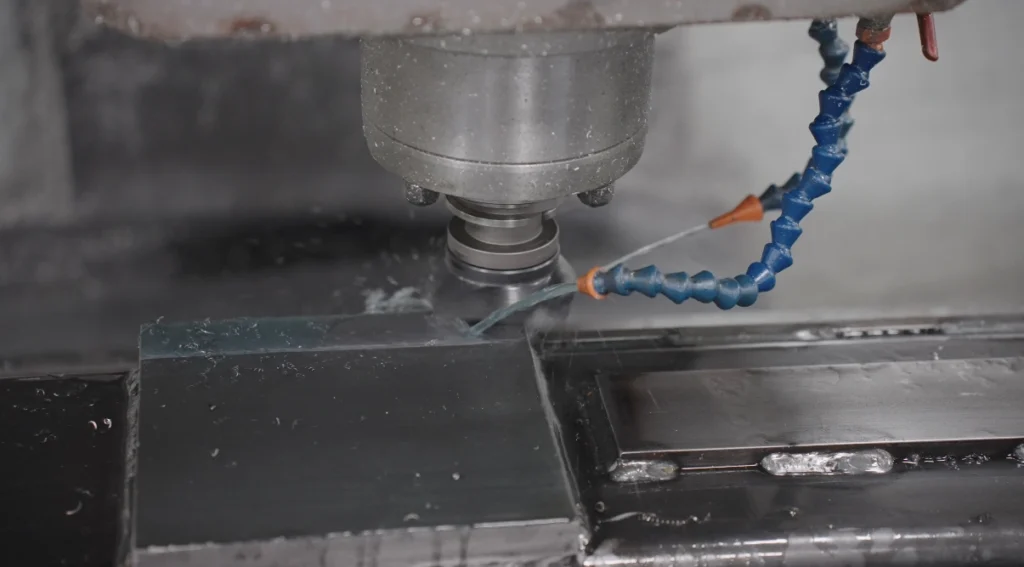

Precision machined parts, assemblies, and weldments

PE-certified fixture, platform, and tooling design

Fixtures, gages, and assemblies

Prototype-to-production parts

Laser and plasma cutting, forming, robotic welding, powder coating

Inspection and quality documentation as required

ACA provides precision machined parts, tooling, and fabrications to support a wide range of production and automation needs. Our team delivers tight-tolerance components, custom fixtures, prototypes, and high-volume production tooling with reliable lead times and consistent quality.

General Capabilities

- Large castings (design and build <44,000 lbs.)

- Steel plate inventory & services

- ¼” to 15” thickness x 120” x 360”, AISI A36, 44W, 1020, 1045, 4140

- Blanchard grinding (max weight 30,000 lbs., 120” x 120” x 60”, 144” diagonal)

- Laser cutting (max 54’ x 12’ x 1”)

- Plasma cutting (max 10’ x 270”)

- Sheet metal fabrication and forming

- Shot peening

- Surface grinding

- MIG, TIG, and Arc welding (AWS & CWB certified)

- Tolerances held to .0002″

Machining

- Vertical mills (max 138” x 320”, 3 axis)

- Vertical mills (max 102” x 165”, 4 axis)

- Horizontal mills (max 80” x 120”, 4-6 axis)

- CNC turning (max 25” x 80” 1-3 axis)

- Planer mills (max 120” x 360” max 2” thickness)

- Wire EDM (max 13” x 21” x 16”)

- 40-ton machining bay crane capacity

- Swiss Screw

Certified Machine Shops

Let Us Solve Your Precision Tooling & Fabrication Challenges

We view our clients not just as customers, but as valuable partners.