ACA’s automation expertise extends well beyond our core offerings. Many projects require supporting systems that enhance production flow, improve reliability, or solve unique engineering challenges. Our additional capabilities cover a wide range of specialized solutions that help customers fill process gaps, streamline manual tasks, and strengthen overall system performance.

Machine Tending Systems

ACA designs machine tending systems that support presses, CNC machining centers, and injection molding equipment to improve throughput, consistency, and uptime.

Controls System Integration

ACA enhances operational efficiency by integrating controls systems across new and existing equipment. Our team handles programming, networking, safety, and communication architecture to ensure reliable machine performance.

Dispensing and Filling

From adhesives to spray applications, ACA builds dispensing and filling systems tailored to your materials and production requirements. We focus on accuracy, repeatability, and long-term reliability to reduce waste and operator workload.

Packaging Systems

ACA provides custom packaging automation designed to handle high-speed packing tasks with consistent accuracy. Solutions include feeding, forming, closing, labeling, and inspection for a wide range of packaging formats.

Robot Repair, Parts, and Service

ACA’s sister company, Bow Robotics, supports robotic systems with troubleshooting, repair, replacement components, and preventive maintenance. Our trained technicians help extend equipment life and reduce downtime.

Material Handling Systems

ACA engineers material handling solutions for mission-critical transfers such as pick and place, palletizing, packaging flow, assembly, and in-process movement. Systems are built to maintain accuracy, safety, and cycle time requirements.

Featured Case Study

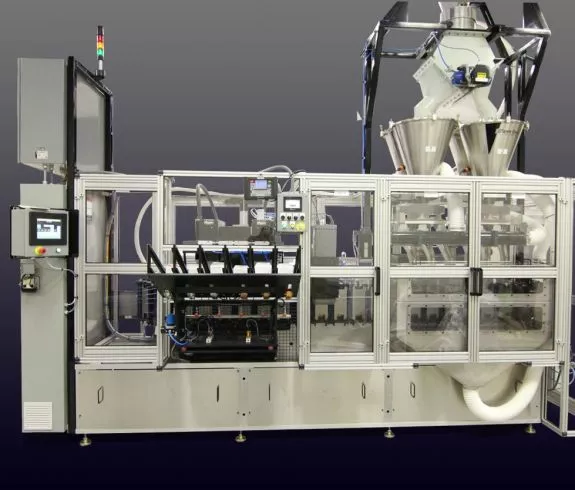

Dry Ingredients Envelope Packer

Challenge: One of our customers in the CPG Industry needed to automate their envelope packing process. Previously, they used a fully manual process with 6 operators which was costly and inefficient.

Solution: ACA designed and built a fully automated machine to assemble and inspect dry ingredients envelopes. The machine feeds, opens, fills, closes, and inspects envelopes, then assembles 3 packs with a header card and applies two staples before releasing to the packaging workers at a rate of 72 envelopes per minute. A single operator keeps this machine fed while a pair of operators fold and fill boxes of 3 packs.

The machine completes 72 envelopes/minute and saves our customer about $500,000 in labor costs per year for one product. The payback period for this machine was 1.51 years.

Video Gallery

Pick and Place Robotic Stacker

Dry Ingredients Envelope Packer

Gasket Feeder System

Cut to Length Cutting Station

Let Us Solve Your Challenges

We view our clients not just as customers, but as valuable partners.