Do you have a process that needs automating? Turn to the experts at ACA.

From designing and building custom turnkey automation equipment to providing precision machine shop services and engineered manufacturing aids, Addtronics Custom Automation partners with manufacturers to solve complex production challenges. Each case study highlights how our custom automation solutions are engineered to meet exact requirements—improving throughput, consistency, quality, and long-term performance.

Explore examples of how ACA has delivered reliable automation systems across a range of applications and industries:

General

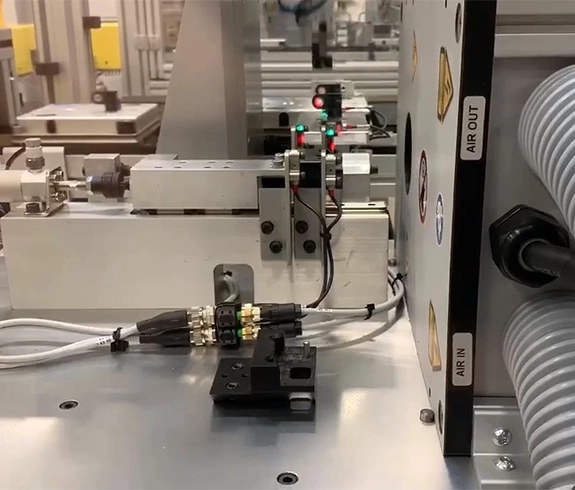

ACA develops custom automation systems that transform complex manufacturing challenges into reliable, high-throughput production solutions. From concept through completion, each system is engineered to meet your exact specifications, performance targets, and operating environment.

Assembly

Our automated assembly solutions increase throughput, tighten tolerances, and improve consistency—ranging from single-station assembly cells to fully integrated, multi-stage automation lines.

Test

ACA designs automated testing systems for leak, functional, and dimensional inspection. These solutions support full data capture, traceability, and compliance with industry and regulatory requirements.

Vision

Our machine vision automation systems deliver real-time inspection with automated reject handling—supporting zero-defect quality control and consistent product validation.

Packaging

ACA provides robotic packaging automation systems for filling, labeling, sealing, and end-of-line handling that keep production moving efficiently while reducing manual labor and variability.